Large enough to handle, small enough to service.

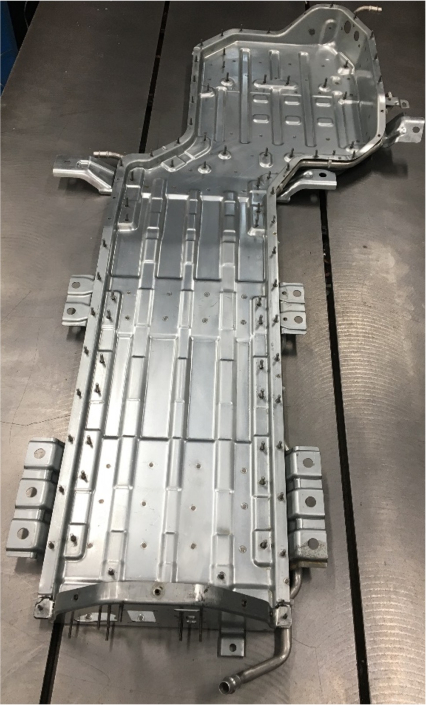

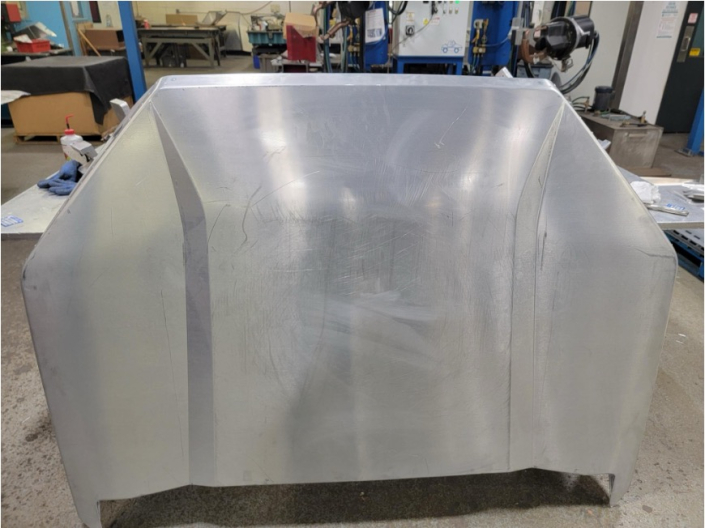

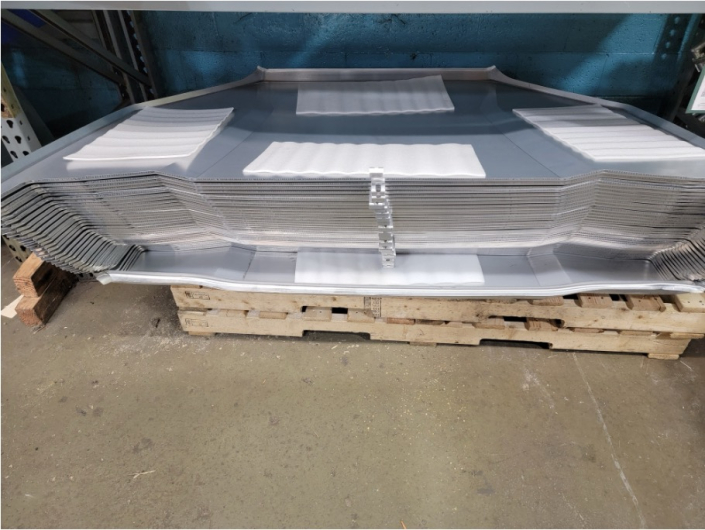

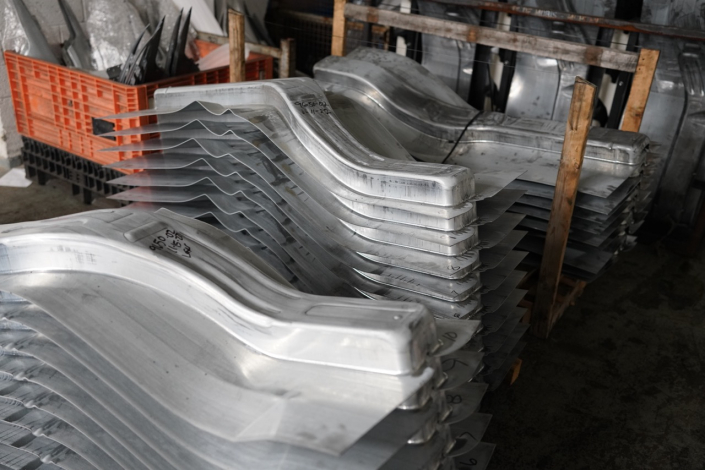

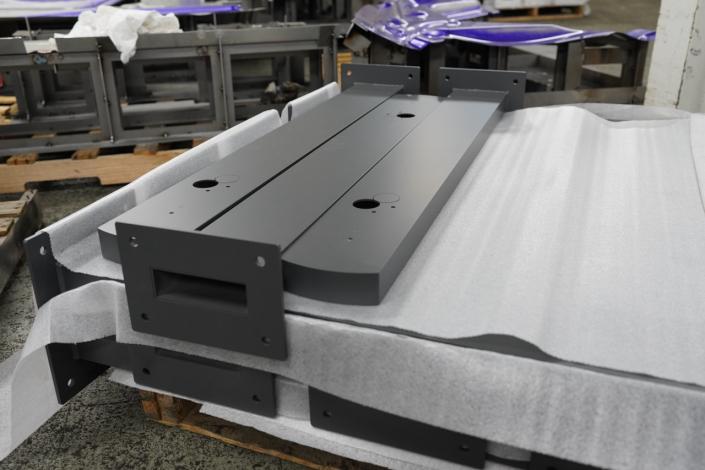

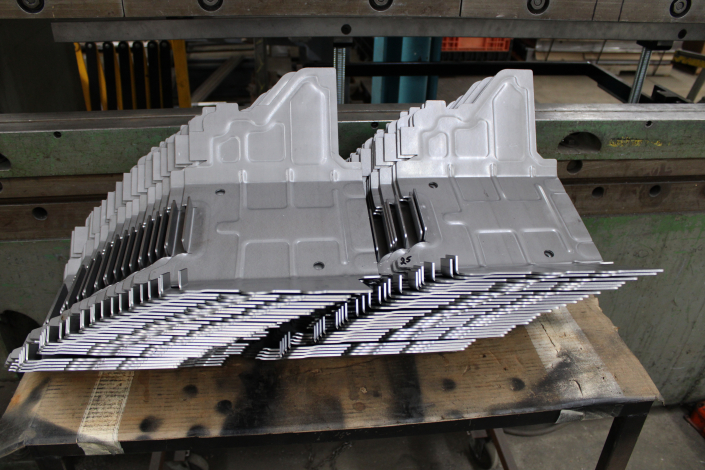

Auto Metal Craft, Inc. is an ISO 9001 : 2015 certified corporation founded in 1949. Over the years, Auto Metal Craft has diligently modernized and expanded its capabilities to include short-run stampings, laser-cutting, part reworking, and CAD model engineering in order to serve OEM and niche manufacturers. We have highly-trained technicians and the latest in technology to make this all possible. Our commitment is to supply our customers with on-time delivery of 100% conforming sheet metal components and assemblies.

MARKETS WE SERVE